What’s the best way to deal with rising energy prices?

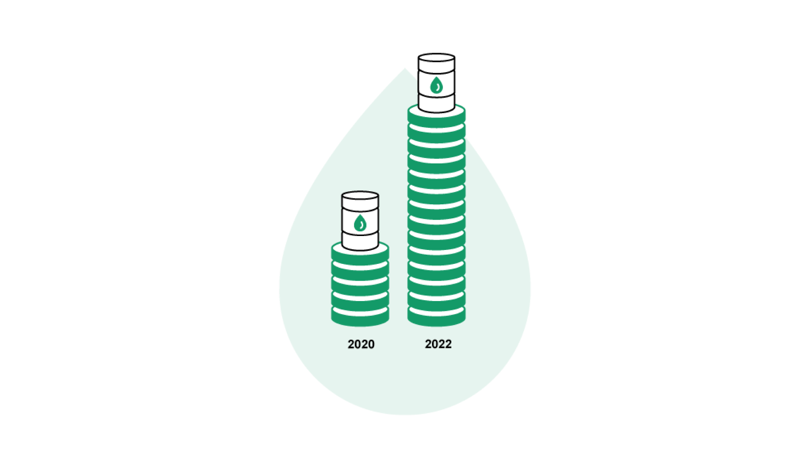

Energy prices are soaring, affecting businesses all over the world. According to the Short-Term Energy Outlook for March 2022 from the US Energy Information Administration (EIA), Brent crude oil was USD 41.69 a barrel in 2020. In the first week of March 2022, daily spot prices for the same commodity closed at almost USD 124 – a 197% increase.

Even though the EIA expects the average price to fall to USD 102 a barrel in the second half of 2022 and to USD 89 in 2023, this forecast depends on several factors that are very hard to predict, including the geopolitical situation and macroeconomic developments. Even if it does hold true, we’re still talking about a 113% increase over 2020.

This has a very real impact on operating expenses (OPEX) for any business that uses fossil fuels. For shipowners, for example, fuel is the single biggest operating cost item – often 50% of the total OPEX. But you can soften the blow of the price increase by reducing energy consumption with technologies and strategies that are available on the market today. Let’s take a brief look at some of them.

Energy optimisation

In many applications, it’s not possible or feasible to replace fossil-fuelled engines, but very often you can optimise operation so they deliver the performance you need on less fuel.

Engines and gensets deliver maximum performance for the fuel consumed if they run at their optimal duty point. You may be able to achieve this by adjusting the settings of your power management system. Perhaps a different combination of engines will use less fuel, and perhaps you can avoid starting some of them altogether. Look for ways to run engine-powered equipment as little as possible, and as energy-efficiently as possible: The less power it consumes, the less power you need to generate.

Energy optimisation can also include replacing existing components with new ones that use less energy. Even if a new pump or generator only uses a couple of percent less fuel than the old one, over a year of operation it adds up to significant savings – particularly with current fuel prices.

Going hybrid or fully electric

If you can add renewable power sources or batteries to your existing fossil-fuelled power plant, you can significantly lower fuel consumption while getting the same performance.

On a ship, batteries can reduce fuel consumption by providing peak shaving, helping you run engines and gensets at their optimum duty point and removing the need to start up additional engines to cover transitory load spikes. You may also be able to run the ship wholly or partially on pure battery power, and if that power comes from wind turbines or similar, power prices may not be affected by the rise in fossil energy costs.

On land, you have several options for developing a hybrid power plant that gives you a wider selection of power sources and reduces your reliance on fossil fuels. Wind, solar, or hydro power do not rely on oil or gas and therefore are not directly affected by energy cost increases. By adding battery storage, you have the same options for peak shaving and load demand handling that you do on a ship. Additionally, you can store renewable power for later use in the battery, running reliably on green power even when there is no wind or sun.

Upgrading to a hybrid or fully electric power plant naturally involves a significant investment, but depending on your fossil fuel consumption, current fuel prices could mean that you can realise return on investment earlier than usual because your OPEX savings quickly add up. For wind farm operators, soaring energy prices mean that retrofit operation investments can be recovered very quickly; read this blog post for more details.

New habits for a new reality

Hardware changes are one thing, but you can also save fuel by changing your approach to using that hardware, and there are many ways of doing it. On a ship, you can save a lot of fuel by adjusting your manoeuvres to fit current conditions – for example by adjusting your course to avoid adverse winds or reducing engine power in shallow waters to reduce the vessel squat effect. Advanced energy management systems are capable of collecting and analysing operational data, giving the crew real-time advice for reducing fuel consumption while adhering to schedules or timetables.

The same basic principle of looking for ways to save energy by adjusting your behaviour can be applied almost everywhere. For example, can you shut down equipment completely in areas that are not being used? How about investing in employee training to raise awareness of energy optimisation and opportunities for fuel savings?

In a new reality where power comes at a higher price, new habits can help you reduce your reliance on fossil fuels and realise OPEX savings.

The starting point for long-term improvement

High energy costs are not a desirable scenario for anyone, but they can provide a starting point for optimisation that can serve your business well in the long term. If (or when) fossil fuel prices drop again, your optimisation efforts will still produce savings compared to your pre-optimisation baseline, and you can also reap benefits such as longer service life and fewer emissions from optimised equipment.

We hope that this blog post has given you some fresh inspiration to make the most of an unfortunate situation. Contact us to learn more about your opportunities for reducing fossil fuel consumption and reducing OPEX.

Read our hybrid power guide

-

Contact us to discuss your options

- 90 years of energy pioneering

- Manufactured at the highest standards

- Superior quality

- Unmatched service and support

- Made in Denmark