How much does a controller cost?

Controllers are crucial to any power production setup, and whenever you need to design, build, or upgrade your system, it is only natural to be curious to know how much you should expect to spend on controllers. Unfortunately, there is no simple answer to this question. It depends entirely on what you need the controllers to do!

Multiple options, several price factors

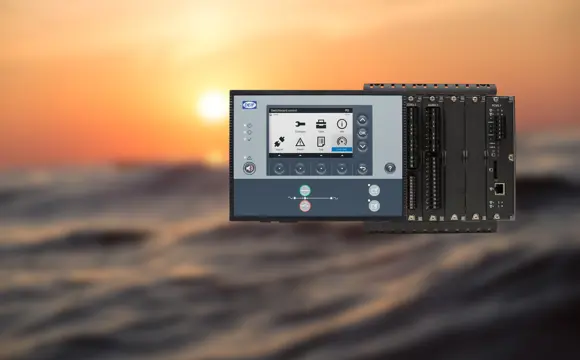

Controllers are used in many different power generation applications on land, at sea, and on wind farms. Depending on the plant configuration, they need to perform different tasks and interface with different systems and components.

Modern, intelligent controllers based on standardised modular software and hardware platforms give you the flexibility to handle most applications right out of the box. To get the performance you need, however, you need to choose the right options or specify your controller very accurately, and there can often be many choices to make.

This flexibility is great news when you need a solution that is exactly right for you; it also means that several things can affect the price you pay. Here are some examples:

- If you are looking to purchase the DEIF AGC-4 automatic genset controller and need it to comply with the German VDE AR-N 4110 or VDE AR-N 4105 regulations, you need to specify option A10 when ordering the controller.

- When ordering a DEIF AWC 500 advanced wind turbine controller, you can choose from several programming environments depending on your requirements: CODESYS or C/C+.

- Several DEIF engine and genset controllers, for example, the PPU 300 used in marine applications, can be specified with an additional display unit allowing crews to see, acknowledge, and reset alarms.

Options such as these allow you to define exactly the solution you need; it also means that there is no one price for all solutions.

Extensive customisation

On the rare occasions that an off-the-shelf controller does not fit your requirements, the manufacturer may be able to customise it by reprogramming the firmware or tailoring I/O or communications options to your application. Needless to say, a customised product is more costly than a standardised offering; in addition to time and resources spent in customising it, there is also a cost towards testing, documentation updates, and approvals (for example from marine class societies). Also important to remember that customisation affects delivery times too.

The product purchase price is just the start

When purchasing a new controller, it is also important to remember that product cost is just one part of the total cost. There are other tasks like engineering the system, programming the controller, commissioning plus some operating costs. For example, in a controller like DEIF AGC-4 the software is maintained and updated for the lifetime of the product by the manufacturer, taking away the fear of bug fixing and updating the system almost the entire life span of the system. On the other hand, when you choose an open PLC platform like AWC 500 with CODESYS, the application software and its maintenance will be your responsibility. This point also becomes essential if you need to reconfigure your controllers a few years from now, for example, because you need to expand or change your setup. Who is going to do it; indeed, who will be capable of doing it, and what will it cost you? Will you need to update your internal documentation, processes, and instructions?

The other important factor is the availability of repair and service over the lifetime. A single PCB integrated controller might have low capital investment, but there is no possibility to repair/service these products. On the other hand, a multi PCB HW offers service possibility, thus not having to discard the total HW within the lifetime of the generating equipment.

Thus the different approaches have different capital and operating cost. So it is all the more important to compare the total cost of ownership throughout the life cycle of the product.

What can you do to make a good budget?

So, as said in the beginning, there is no easy answer: The cost of the system will depend entirely on the choices you make for your system to be reliable, flexible, scalable – now and in future. The best way to do this is list down the things you need to accomplish with the new system, read some case studies and whitepapers from relevant manufacturers and more importantly talk to experienced industry professionals to get details, good advice, and more information. Then you are able to choose the one that fits the best for you. Happy hunting!

Find your nearest DEIF office, and contact us to discuss your requirements

-

Contact us to discuss your options

- 90 years of energy pioneering

- Manufactured at the highest standards

- Superior quality

- Unmatched service and support

- Made in Denmark