Benefits over PLC solutions in critical power applications

In many applications, power failures are unacceptable, and systems designed for critical power are therefore needed. While PLCs have traditionally been used to control critical power systems, multi-master power management systems (MM PMS) are a viable alternative. They offer full redundancy and additional benefits such as improved performance for removing single points of failure, ease of use, and financial savings.

A critical power system is designed to ensure power at all times, even when grid power fails. Backup power is typically supplied by generators or batteries; these power sources are controlled by one or more controllers that detect when grid power is unstable or unavailable. When the need arises, they bring one or more power sources online to compensate for lacking grid power. Needless to say, these controllers need to be extremely reliable.

PLCs: the traditional approach

Critical power systems have traditionally been designed with programmable logic controllers (PLCs). Such systems will typically have one master PLC that monitors all power sources, breakers, and other important system components.

Using just one master PLC, however, makes the system vulnerable to controller failure. All system components deteriorate over time, and if the master PLC does fail, it takes down the whole system. In many applications, this is an unacceptable risk, as power failures could result in loss of data, performance, productivity, money – or human life.

Another potential problem is that if your business expands and your critical power system needs to expand with it, this is more costly with PLC solutions: The PLC programme was developed by one particular programmer based on his particular knowledge and understanding of the system, and the specificity of the programme makes it vulnerable in the long term.

MM PMS: the value-added alternative

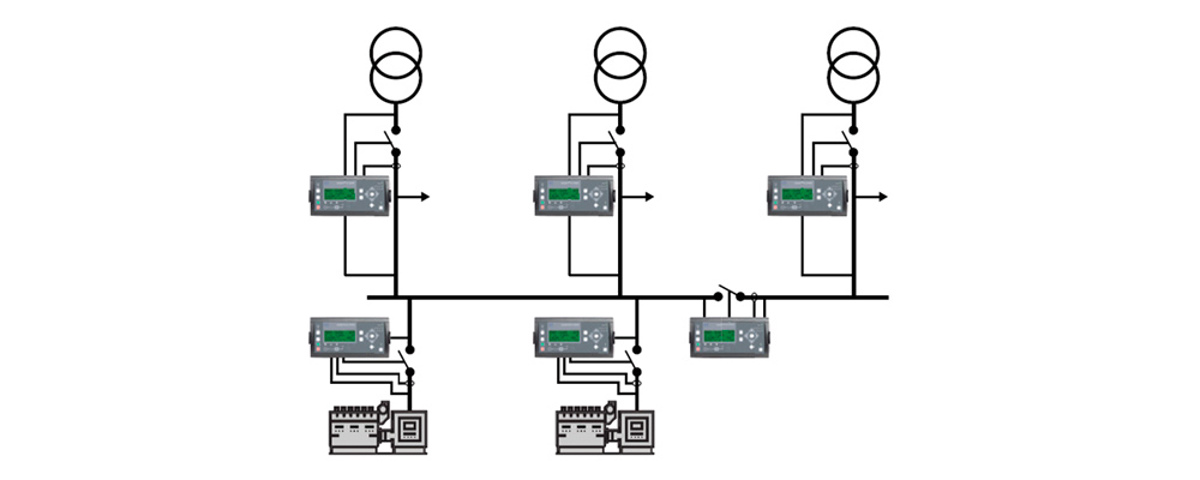

In mission-critical applications, critical power systems should therefore be designed with redundant control options to safeguard against master controller failure. This can be done by designing and implementing a control architecture that uses several redundant controllers in a multi-master power management system (MM PMS), using redundant communication lines with separate outputs.

In an MM PMS, there is a controller on every single power source, and optionally on important switches such as the bus tie breaker. All controllers are linked in a data network with full redundancy and have discrete power supplies.

As in a PLC-based system, one controller is the master controller. In an MM PMS, however, another controller takes over the master controller role if the original controller fails. With redundant communication lines and discrete controller power supplies, the MM PMS provides full redundancy in every important aspect of the critical power system control solution.

Additional benefits

In addition to ensuring full redundancy, MM PMS solutions offer benefits that would not be possible, or would be difficult or costly to achieve, using PLCs. For example, controllers could offer features like Close Before Excitation (CBE), also known as Dead bus sync or Black bus sync, peak shaving, and load distribution, and the standardised software platform means that you can save time and money on design and operation of the system.

In short, an MM PMS gives you built-in redundancy, ease of use and serviceability, and value-added features that improve critical power system performance and uptime. This is good news for your critical power system, and for your customers, colleagues, and end-users who rely on it. Read more about MM PMS solutions in the FREE whitepaper from DEIF!

Download the FREE whitepaper from DEIF

Read more about the DEIF AGC-4 genset controller which is designed for MM PMS applications

Read our guide about data centres

-

Contact us to discuss your options

- 90 years of energy pioneering

- Manufactured at the highest standards

- Superior quality

- Unmatched service and support

- Made in Denmark